By Gary Ilcyn, CEO and Jaguar Enthusiast at Jagbits Inc.

The Jaguar MK2, a quintessential British sports sedan from the late 1950s and early 1960s, is renowned for its sleek design, luxurious interior, and powerful performance. One of the critical components contributing to its celebrated ride and handling is its front suspension system. In this article, we delve into the intricacies of the MK2’s front suspension, exploring its design, components, maintenance, and common issues, providing a comprehensive understanding for enthusiasts and mechanics alike.

Historical Context and Development

Launched in 1959, the MK2 revolutionized its predecessor with groundbreaking improvements. Its new independent front suspension dramatically boosted performance, showcasing Jaguar’s unwavering dedication to innovation and excellence.

Influence of Motorsports

Jaguar’s involvement in motorsports significantly influenced the design of the MK2’s front suspension. The lessons learned on the racetrack were applied to their road cars, resulting in a suspension system that offered superior handling and ride comfort. The double-wishbone setup, a hallmark of racing car suspension, was adapted for the MK2, providing it with exceptional agility and stability.

Design and Engineering

The front suspension of the Jaguar MK2 is a double-wishbone, independent suspension system, a design that was advanced for its time. This setup provides excellent handling and ride comfort, distinguishing the MK2 from its contemporaries. The double-wishbone design allows each wheel to move independently, which helps maintain tire contact with the road, enhancing grip and stability.

Components of the Front Suspension

1. Upper and Lower Wishbones: The core of the suspension, these control arms connect the wheel hubs to the vehicle’s chassis. They are responsible for maintaining the wheel’s vertical position and controlling the camber angle.

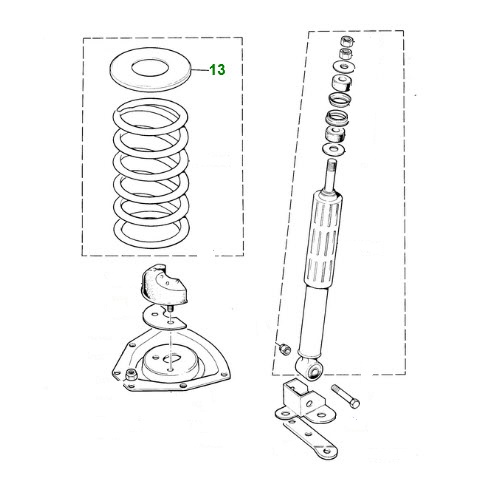

2. Coil Springs: Mounted between the wishbones and the chassis, coil springs absorb shocks from road irregularities, contributing to a smoother ride.

3. Shock Absorbers: These hydraulic dampers work alongside the coil springs to control the rebound and compression of the suspension, ensuring the vehicle maintains stability and comfort.

4. Anti-Roll Bar: Also known as the sway bar, this component connects the left and right sides of the suspension, reducing body roll during cornering and enhancing handling.

5. Ball Joints: These spherical bearings connect the wishbones to the wheel hubs, allowing for smooth articulation of the suspension components.

6. Bushings: Rubber or polyurethane bushings are used in the wishbones and other joints to absorb vibrations and reduce noise.

Detailed Examination of Key Components

Upper and Lower Wishbones

The wishbones, often referred to as control arms, are pivotal in the front suspension system. They are typically made of stamped steel or cast iron and are designed to handle significant forces during driving. The wishbones’ geometry ensures that the wheels remain in the optimal position relative to the road surface, which is crucial for maintaining grip and handling.

Upper Wishbone: The shorter upper wishbone compared to the lower one results in a negative camber gain during suspension compression. This tilts the top of the wheel inward as it compresses, enhancing grip and performance while cornering.

Lower Wishbone: The extended lower wishbone ensures a rock-solid link to the chassis, bearing most of the vehicle’s weight with unwavering stability.

Coil Springs

The coil springs in the front suspension of the MKII are designed to absorb and dissipate energy from road impacts. Made from high-tensile steel, these springs are calibrated to provide a balance between ride comfort and handling performance. Over time, springs can sag or break, necessitating periodic inspection and replacement.

Shock Absorbers

Shock absorbers, or dampers, are essential in managing suspension movement. They curb excessive bouncing by absorbing energy from the coil springs. The Jaguar MK2 features telescopic shock absorbers filled with hydraulic fluid that resists piston motion within the cylinder.

Function: Shock absorbers convert kinetic energy from suspension movement into thermal energy, which is then dissipated.

Maintenance: Leaking fluid, reduced damping performance, and unusual noises are signs that shock absorbers need servicing or replacement.

Anti-Roll Bar

The anti-roll bar is essential for maintaining the vehicle’s stability during cornering. It reduces body roll by distributing the load across the suspension, improving grip and handling.

Design: The bar is a torsion spring that twists when the vehicle leans, transferring force from one side of the suspension to the other.

Performance: A thicker anti-roll bar can reduce body roll but may lead to a stiffer ride. Conversely, a thinner bar offers more comfort but less roll resistance.

Ball Joints and Bushings

Ball joints and bushings are the backbone of your suspension system, offering crucial flexibility and damping for a seamless ride.

Ball Joints: These components allow for the pivoting of the wishbones relative to the wheel hub. Wear and tear can lead to play in the steering and suspension, necessitating replacement.

Bushings: Made from rubber or polyurethane, bushings absorb minor vibrations and shocks. Over time, they can deteriorate, leading to increased noise and harshness.

Maintenance and Upkeep

Maintaining the front suspension of a Jaguar MK2 is crucial for ensuring its legendary ride quality and handling characteristics. Regular inspection and timely replacement of worn components can prevent more significant issues and preserve the vehicle’s performance.

Inspection Checklist

1. Visual Inspection: Regularly check for signs of wear, damage, or corrosion on all suspension components.

2. Suspension Play: Test for play in the suspension by rocking the wheel. Excessive movement indicates worn ball joints or bushings.

3. Shock Absorber Test: Check for leaks and perform a bounce test to assess the shock absorbers’ condition.

4. Alignment Check: Ensure the wheels are properly aligned to prevent uneven tire wear and handling issues.

5. Lubrication: Keep all moving parts well-lubricated to reduce wear and prevent corrosion.

Common Issues and Solutions

Sagging Springs: Sagging coil springs can ruin your ride’s height and handling. Swap them out to bring back that smooth, original performance.

Worn Bushings: Bushings degrade with age and exposure to the elements. Replacing them with high-quality rubber or polyurethane bushings can improve ride comfort and reduce noise.

Leaking Shock Absorbers: Leaks are a clear sign that shock absorbers need replacement. Opt for high-quality replacements to maintain handling performance.

Corroded Components: Rust silently eats away at your suspension parts, compromising their strength. Keep them robust with regular cleaning and rust-proofing to ensure a smoother, safer ride.

Note:

* This article has been peer-reviewed and held to the highest editorial standards.

** Image may not represent actual part.

Upgrading the Front Suspension

Jaguar MK2 enthusiasts can transform their ride with a range of thrilling upgrades. Boost your car’s handling, comfort, and overall driving experience effortlessly.

Performance Coil Springs

Switching to performance coil springs can transform your ride. Lowered height and reduced body roll sharpen handling, while stiffer springs deliver a more responsive, thrilling drive.

Adjustable Shock Absorbers

Adjustable shock absorbers allow for fine-tuning of the suspension’s damping characteristics. This customization enables drivers to optimize their vehicle for different driving conditions, from comfortable cruising to spirited driving.

Polyurethane Bushings

Upgrade your suspension with polyurethane bushings for unmatched responsiveness and durability. Unlike rubber, polyurethane offers a firmer feel and superior handling. Transform your drive today!

Upgraded Anti-Roll Bar

An upgraded anti-roll bar can further reduce body roll and improve cornering stability. Performance bars are often thicker and stiffer, providing better resistance to torsion.

Comparative Analysis

Comparing with Contemporaries

When compared to other classic cars from the same era, the Jaguar MK2’s front suspension stands out for its advanced design and superior handling characteristics. While many vehicles of the time relied on simpler, less effective suspension systems, the MK2’s double-wishbone setup provided a more sophisticated and capable solution.

Unique Features

The independent double-wishbone design was not commonly found in sedans of the 1950s and 1960s. This gave the MK2 a competitive edge in terms of ride quality and handling. The combination of coil springs, telescopic shock absorbers, and a robust anti-roll bar contributed to a balanced and responsive driving experience that was rare for its class.

Real-World Performance

Owner Testimonials

Jaguar MK2 owners rave about its silky ride and nimble handling, crediting the expertly crafted front suspension. Despite its vintage status, the MK2 competes fiercely with modern cars in comfort and driving joy.

Peter Donovan, Classic Car Enthusiast: “I’ve driven countless classic cars, but the MK2 is unforgettable. Its front suspension delivers a ride that’s both silky and agile, transforming winding roads into pure driving bliss.”

Janet Sonith, Vintage Car Racer: “The MK2 grips the track like a beast. Its suspension hugs every corner, inspiring me to push harder with unwavering confidence.”

Performance in Various Conditions

The Jaguar MK2’s front suspension excels in every scenario. In the city, it glides over potholes and bumps effortlessly, ensuring a smooth ride. On highways, it offers rock-solid stability and minimal body roll for relaxed long-distance drives. Hit the winding roads or racetrack, and its precision and responsiveness transform driving into an exhilarating experience with unmatched control.